|

Crusher Liner Plate

Crusher Liner Plate Specification

- Surface Finish

- Smooth/Polished

- Capacity

- Heavy Duty

- Features

- High Wear Resistance, Corrosion Resistance, Long Service Life

- Usage & Applications

- Industrial

- Size

- Customized

- Shape

- Rectangular

- Product Type

- Crusher Liner Plate

- Material

- MS

- Technology

- Casting

- Surface Treatment

- Painted

- Dimension (L*W*H)

- As per requirement

- Weight

- Standard/Custom

- Color

- Red

- Thickness

- Customizable

- Grade

- Industrial Grade

- Hardness

- 50-60 HRC

- MOQ

- As per requirement

- Impact Strength

- High

- Compatibility

- Suitable for All Types of Crushers

- Replaceability

- Easy to Install and Replace

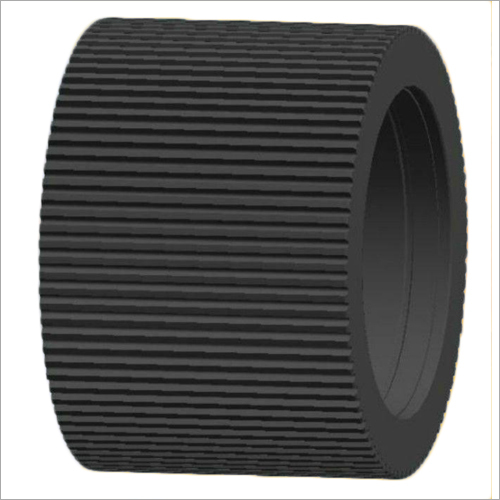

- Pattern

- Ribbed/Plain

- Packaging Type

- Wooden Box/Pallet

- Mounting Type

- Bolted

- Edge Type

- Machined

Crusher Liner Plate Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 7 Days

About Crusher Liner Plate

Competitive Edge and Unique Benefits of Crusher Liner Plate

Designed for heavy-duty industrial applications, our Crusher Liner Plate exhibits high wear resistance and impressive corrosion protection. Its customizable size and easy-to-install bolted mounting ensure seamless compatibility for all crusher models. With a choice of ribbed or plain patterns and reliable replaceability, users gain reduced downtime and masterful operational efficiency. The high impact strength and superlative hardness make it an enlightened choice for demanding environments, offering a long service life and optimal performance in every use.

Packaging Details, Supply Policy, and Certifications

Our Crusher Liner Plate is shipped in sturdy wooden boxes or pallets, ensuring safe delivery to your site. Each package is carefully designed for secure handling, whether for single orders or bulk supply. On request, sample policy accommodates evaluation prior to final shipment. We maintain packaging standards to meet industrial certification requirements, guaranteeing every plate arrives with authenticity and quality assurance. Advanced supply chain and tested processes make procurement streamlined, with tailored documentation available upon request.

FAQs of Crusher Liner Plate:

Q: How is the Crusher Liner Plate installed and replaced?

A: The Crusher Liner Plate features a bolted mounting type, making it straightforward to install or replace, reducing downtime and ensuring continued efficiency in your crusher operations.Q: What benefits does the ribbed or plain pattern offer for crusher applications?

A: Ribbed and plain patterns allow users to choose the best option for their operation, optimizing material flow and wear resistance for different industrial requirements.Q: When is it necessary to replace the Crusher Liner Plate?

A: Replacement is advised when significant wear, reduced efficiency, or visible damage occurs, ensuring that your crusher continues to operate at optimal performance levels.Q: Where can I use the Crusher Liner Plate?

A: These plates are suitable for all types of crushers, making them versatile for a wide range of industrial, mining, or manufacturing settings.Q: What is the process for customizing thickness and size?

A: You can specify your requirements during ordering; our fabrication team will produce the plates with your desired thickness, length, width, and hardness to suit your application.Q: How does the painted and polished surface finish benefit the plates usage?

A: Painted and polished finishes deliver enhanced corrosion resistance and a smooth surface, which prolongs service life while maintaining high aesthetic and functional standards.

Price 2000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 7 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crusher Spare Parts Category

Ring Hammer

Price 2500 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Machine Accessories

Material : Mild Steel

Color : Metallic Grey

Surface Finish : Smooth

Jaw Crusher Spares Parts Toggle Plate

Price 8000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Jaw Crusher Spares Parts Toggle Plate

Material : High Maganese Steel

Color : Metallic Grey

Surface Finish : Polished

Impact Blade

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Impact Blade

Material : Metal

Color : Silver

Surface Finish : Smooth

Hard Facing Wear Plate

Price 2000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Hard Facing Wear Plate

Material : Mild Steel

Color : Red

Surface Finish : Polished

|

SHREE BALAJI ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |